Wind power converts kinetic energy in moving air into electricity using wind turbines. It is a mature renewable technology that has grown rapidly in the last decade and is a core component of most plans to de-carbonize electricity systems. Significant new capacity was added globally in recent years, showing continued expansion of the sector.

The technology has reached commercial scale across both onshore and offshore projects, with turbines becoming larger and more efficient. Advances in aerodynamics, materials and digital monitoring have steadily reduced costs and improved reliability. Wind power now competes directly with fossil fuel generation in many regions without the need for subsidies.

Its scalability allows projects to be developed from small community installations to multi gigawatt offshore farms. Governments, investors and utilities increasingly view wind energy as a critical element in achieving long term climate and energy security goals.

What is Wind Power?

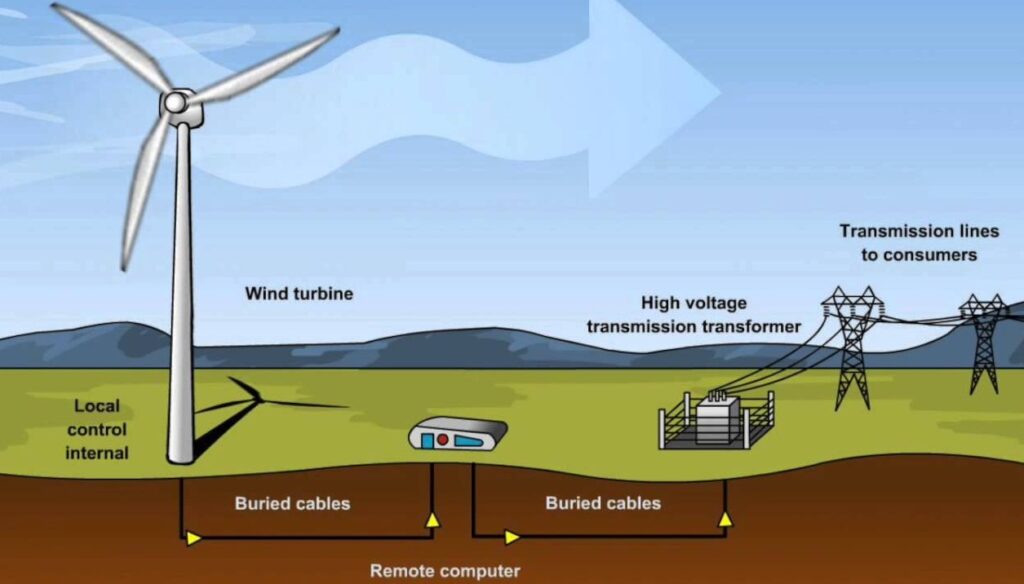

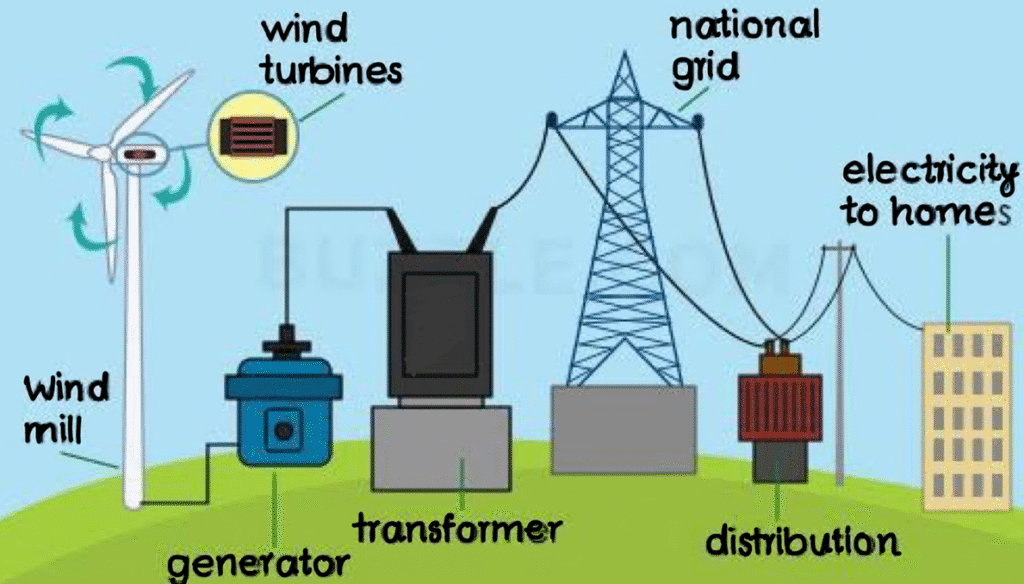

Wind power is a form of renewable energy that uses the natural movement of air in the Earth’s atmosphere to generate electricity. The process begins when wind turns the blades of a wind turbine. These blades are connected to a rotor which spins a shaft attached to a generator, and the generator converts the rotational energy into electrical energy.

The amount of power generated depends on the wind speed, the swept area of the blades, and the efficiency of the turbine design. Modern wind turbines can operate in a wide range of wind conditions and are equipped with control systems to optimize performance and protect the equipment during strong winds.

Wind power is considered one of the cleanest energy sources because it does not emit carbon dioxide or other greenhouse gases during operation. It can be harnessed onshore in open land areas or offshore where wind speeds are generally higher and more consistent. As technology has advanced, the cost of producing electricity from wind has decreased, making it competitive with traditional fossil fuels in many regions.

In global energy strategies, wind power is viewed as a key contributor to sustainable electricity generation, energy independence, and the reduction of greenhouse gas emissions.

How wind Power is produced?

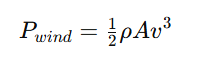

The instantaneous power carried by wind through an area A is

Pwind = the power available in the wind

ρ = the density of air (about 1.225 kg/m³ at sea level)

A = the area swept by the wind turbine blades (like the circle the blades make when they spin)

v = the speed of the wind

Because power scales with the cube of wind speed, small changes in wind speed produce large changes in available power.

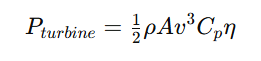

Since no turbine can extract all of the wind’s energy, we account for:

Where:

- Cp = Power coefficient (efficiency of capturing wind energy), limited by the Betz Limit to about 0.593 (59.3 percent maximum)

- η = Mechanical and electrical efficiency of the turbine system (gearbox, generator, etc.), often 0.85–0.95

Here is an Example:

- Blade radius r=40 m → A=πr2=5026.5 m²

- Wind speed v=12 m/s

- Air density ρ=1.225 kg/m³

- Cp=0.45 and η=0.90

P=0.5×1.225×5026.5×12³×0.45×0.90

P≈2.88 MW

No turbine can extract all of that power. The fundamental aerodynamic limit is given by Betz law which shows a maximum theoretical capture of about 59.3 percent of the kinetic energy in an open airflow. Practical large turbines reach a substantial fraction of that theoretical limit at optimal operating point.

Turbine design and principal components

Rotor and Blades

The rotor swept area is the single most important geometric parameter for energy capture. Designers choose blade length and chord and airfoil shapes to match site wind speeds and structural limits. Larger rotors increase energy capture but impose stronger loads and higher material demands.

Drive Train and Power Conversion

A modern utility scale turbine consists of a rotor hub and blades, main shaft and bearings, a gearbox in many designs, a generator, power electronics and control systems. Some designs use direct drive generators that remove the gearbox. The whole assembly plus tower and foundation form the turbine system.

For a technical review of drivetrain technologies and their tradeoffs consult detailed engineering reviews.

Control Systems

Turbines use two main control strategies to limit loads and regulate power. Pitch control changes blade angle to regulate power and protect the turbine at high wind speeds. Yaw control aligns the rotor with the wind. Modern turbines include active sensors and controllers to optimize performance and reduce fatigue.

Onshore versus offshore

Offshore sites commonly have higher average wind speeds and smoother profiles which raise capacity factors. Offshore turbine sizes have grown rapidly with rotor diameters and nameplate ratings increasing to take advantage of those stronger winds.

Floating foundation technology is enabling deeper water deployment and opening new areas for development. Recent industry reports and market summaries document these trends and the record new installations in recent years.

Performance metrics for Wind Power

Capacity factor

Capacity factor is actual energy produced divided by the energy the plant would produce if it operated at rated power all the time. Typical utility scale onshore farms have capacity factors that vary by resource and site and often range from low twenties percent to the mid forties percent depending on wind regime and turbine choice. Offshore farms commonly achieve higher capacity factors than onshore.

Availability and reliability

Availability measures the percentage of time turbines are able to produce power when wind conditions permit. Technical design, maintenance strategies and quality of components determine long term reliability and availability.

Grid integration and system impacts

Wind power is variable and partially unpredictable. Integrating growing shares of wind into grids raises challenges in balancing, frequency control and reserve procurement. Solutions include improved forecasting, flexible generation, demand response, grid scale storage and strengthened transmission networks.

Technical reviews of grid integration challenges and mitigation methods are useful resources for system planners.

Economics and cost trends of Wind Power

Levelized cost of energy for wind has declined substantially over the last two decades due to larger turbines, improved reliability, better project siting and supply chain learning. Independent assessments show sharp declines in weighted average costs in recent years for new projects relative to fossil fuel sources.

Cost competitiveness varies by region resource and policy environment. For recent global cost summaries see international renewable energy reports.

Technical analysis of Wind Power

The following section provides a detailed technical analysis of wind power systems.

Aerodynamics and tip speed ratio

Blade design targets an optimal tip speed ratio which is the ratio of blade tip speed to wind speed. Operating near the designed tip speed ratio maximizes aerodynamic efficiency. Blade twist and taper plus airfoil selection manage the local angle of attack along the span.

For example, modern offshore turbines with blades exceeding one hundred meters in length are designed with variable pitch control to maintain an optimal tip speed ratio under different wind conditions. Computational fluid dynamics simulations are often used during design to predict flow separation and turbulence effects, allowing engineers to refine blade geometry for higher efficiency.

Structural dynamics and fatigue

Wind turbine blades and tower experience cyclic loads due to turbulence shear and yaw misalignment. Fatigue life prediction uses load spectra, material S N curves and safety factors. Designers apply pre design simulations using aeroelastic models to ensure components meet lifetime requirements.

A practical example is the use of carbon fiber reinforced polymers in the spar caps of large blades which reduces weight while increasing fatigue resistance. These advanced materials combined with detailed finite element analysis help extend turbine lifetimes beyond twenty years even under harsh operating conditions.

Power electronics and grid codes

Modern turbines use power converters to produce grid quality electricity and to provide ancillary services. Grid codes increasingly require turbines to provide functions such as low voltage ride through and inertial response. Power converter sizing and control algorithms are critical to meeting these obligations.

For instance, doubly fed induction generators and full converter synchronous generators are two common approaches that meet grid compliance while offering reactive power support. Advanced digital controllers allow turbines to act more like conventional power plants, improving overall grid stability during fluctuations.

Resource assessment and siting

Accurate wind resource assessment uses long term measurement and mesoscale modelling. Effective siting balances maximizing energy capture with minimizing costs such as foundations and grid connection. Offshore siting must also consider seabed conditions and marine constraints.

A detailed example is the use of light detection and ranging systems that measure vertical wind profiles and turbulence intensity at prospective sites, which improves prediction accuracy. Combining these measurements with mesoscale climate models allows developers to calculate expected annual energy production and optimize turbine layout across a wind farm.

Final Thoughts

Wind energy stands out as one of the cleanest sources of power, with life cycle carbon emissions far lower than those of fossil fuel generation. Successful deployment depends not only on technology but also on thoughtful siting that considers impacts on wildlife, landscape quality and community acceptance.

Thorough environmental assessments combined with transparent community engagement can minimize conflicts and ensure shared benefits. Looking ahead, the industry is expected to advance through larger turbines in offshore environments, lighter and stronger blade materials, and smarter digital control systems that use tools such as digital twins and machine learning for predictive maintenance.

Hybrid projects that integrate wind power with energy storage will also play a vital role in delivering more reliable and stable electricity to meet future energy demands.